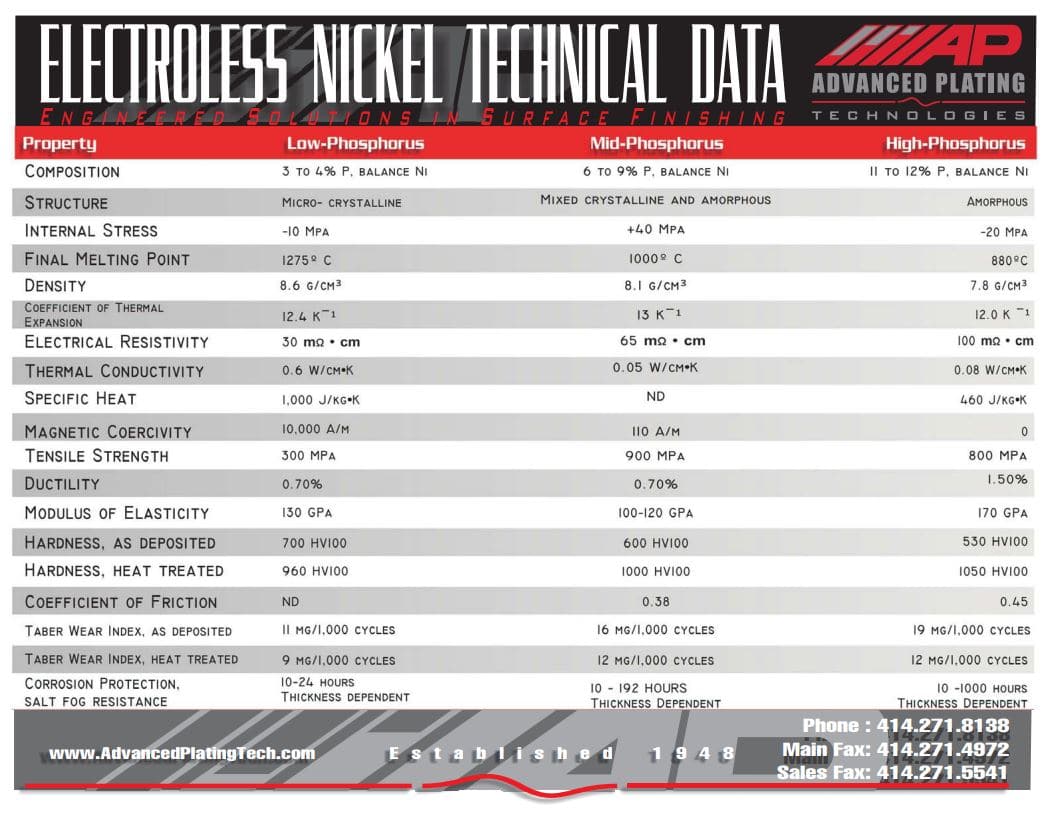

Electroless nickel plating on aluminum comply with mil c 26074 ams c 26074 astm b733 and ams 2404 electroless nickel plating aluminum produces very uniform hard and lubricious coatings without an externally applied electric current.

Nickel plating aluminum specification.

Plating specifications general information page 13 reference only april 2018 nickel qq n 290 coating for steel copper copper alloys zinc and zinc alloys.

Can be similar in color to.

Apt can also certify nickel plating services to iso 1458 ams 2423 and ams 2403 well as most company specific nickel specifications.

Nickel deposits containing various types of additives.

Nickel deposits containing dispersed submicron particles.

Electroless nickel plating specifications the two most common electroless nickel plating services certified by advanced plating technologies are mil c 26074 astm b733 and ams 2404.

Nickel plating services nickel plating specifications the two most common nickel plating services certified by advanced plating technologies are qq n 290 astm b689.

Within the astm b733 electroless nickel plating specification there is an additional category known as service condition.

The nickel plating shall have columnarcrystalline structure before anneating.

Astm b733 also specifies five 5 types of electroless nickel plating.

Apt also can certify electroless nickel plating services to iso 4527 and ams 2405 as well as most company specific electroless nickel specifications.

Can be dyed practically any coloror shade black blu red etc type ii 00020 0010.

Nickel can be deposited soft or hard dull or bright depending upon process used and conditions employed in plating.

Classes grades of sulfamate nickel plating.

The astm specification also discusses testing methods and sampling requirements.

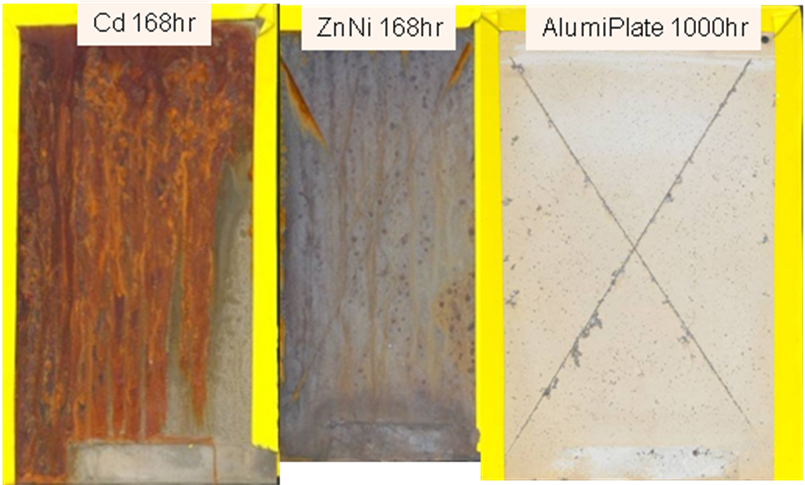

Service condition is based on the thickness starting with sc0 for minimum service requirements and continuing up to sc4 for severe service requirements.

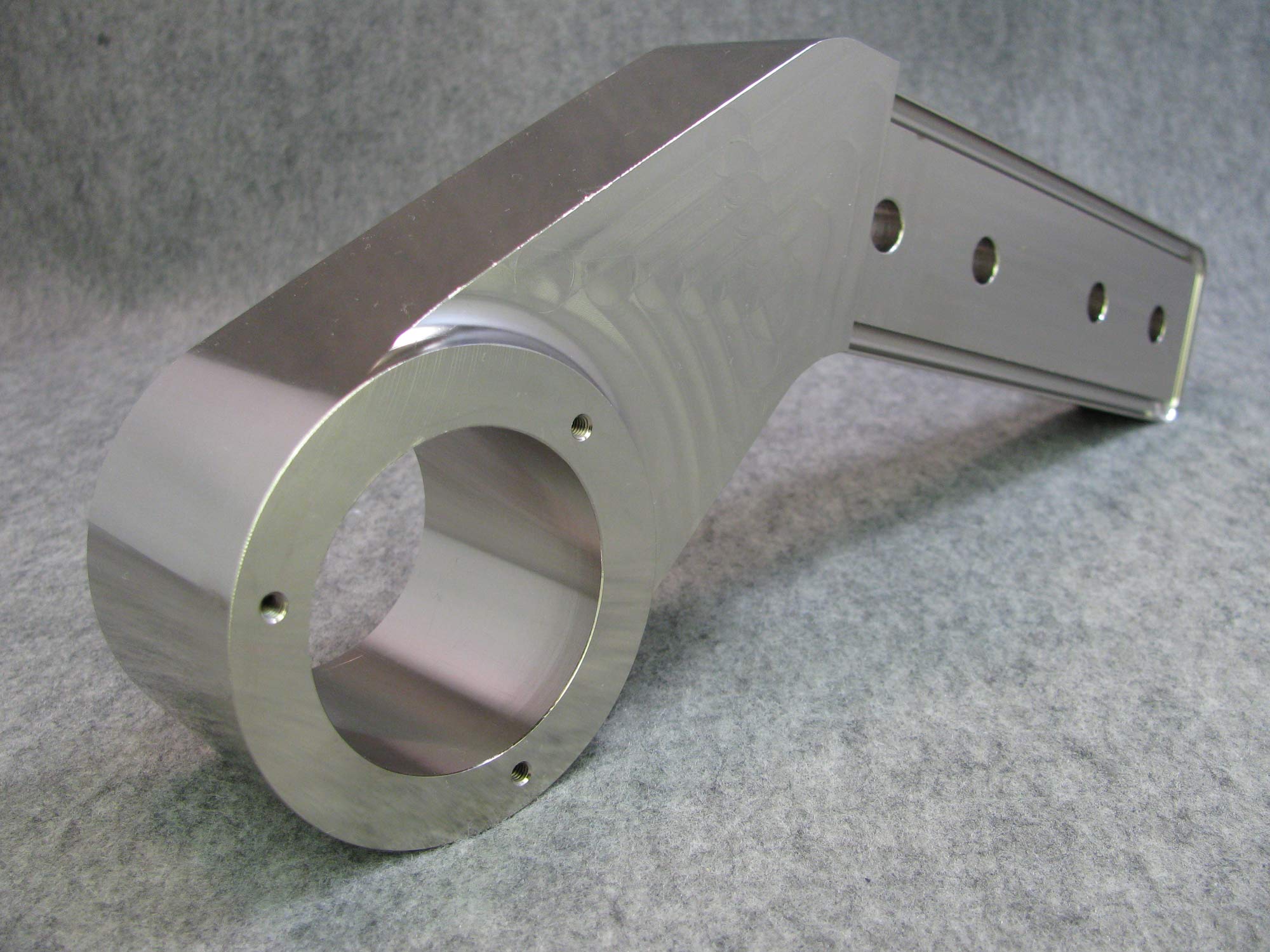

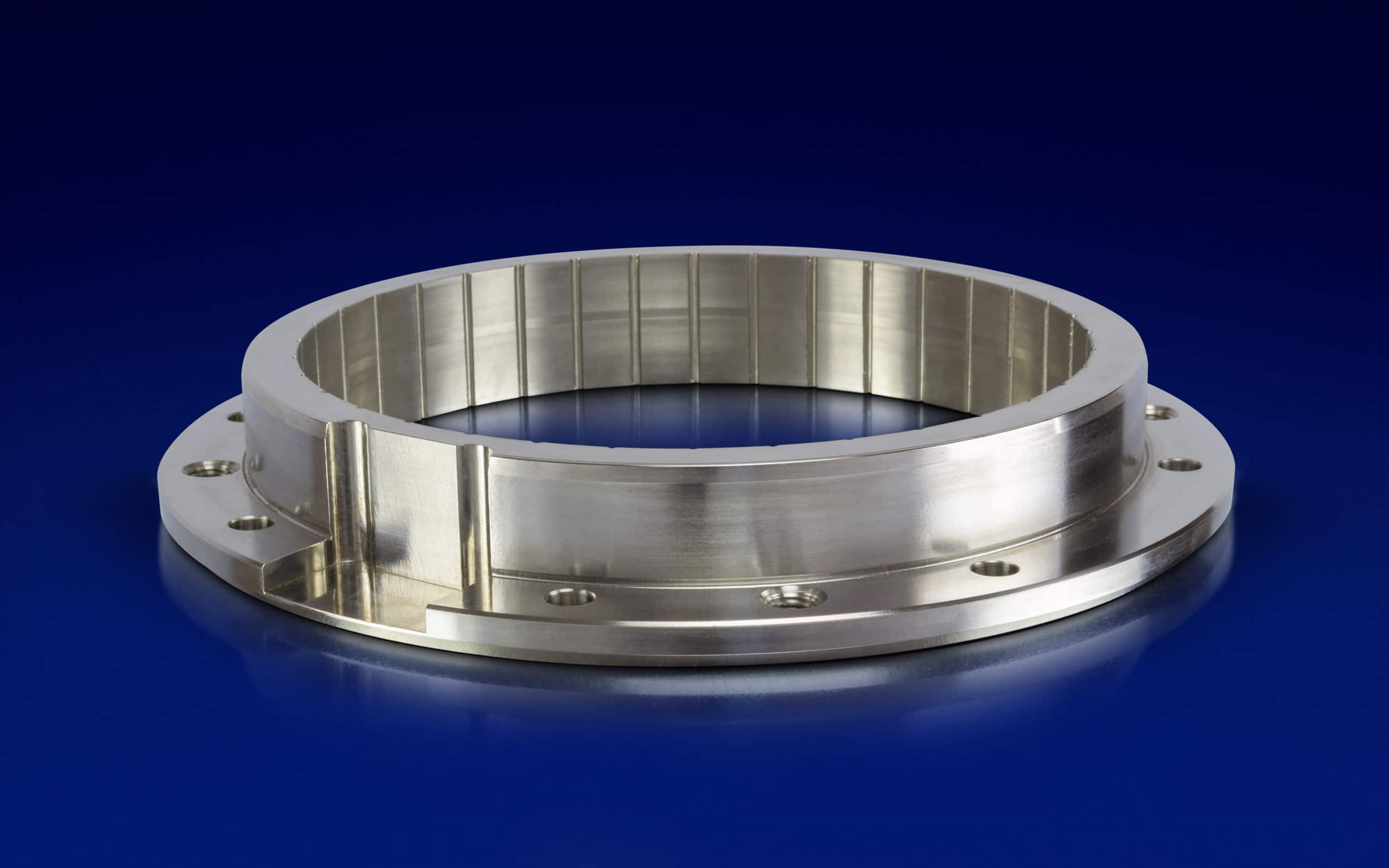

While aluminum features a high strength to weight ratio it is softer than many other metals.

A nickel plated coating will increase the hardness of the aluminum alloy substrate and increase corrosion resistance.

If you are involved with nickel plating or specify nickel plating you should be familiar with this specification.

Depending on your application requirements we routinely apply coatings as thin as 0 0002 per surface or as thick as 0 002 per surface holding tolerancing.

Nickel deposits containing no additives.

Sulfamate nickel coating specifications set the requirements for plating steel aluminum and copper substrates as well as the standards for cleaning and the best underplating processes to prevent degradation of the base material.